LED Display Quality Control

About us

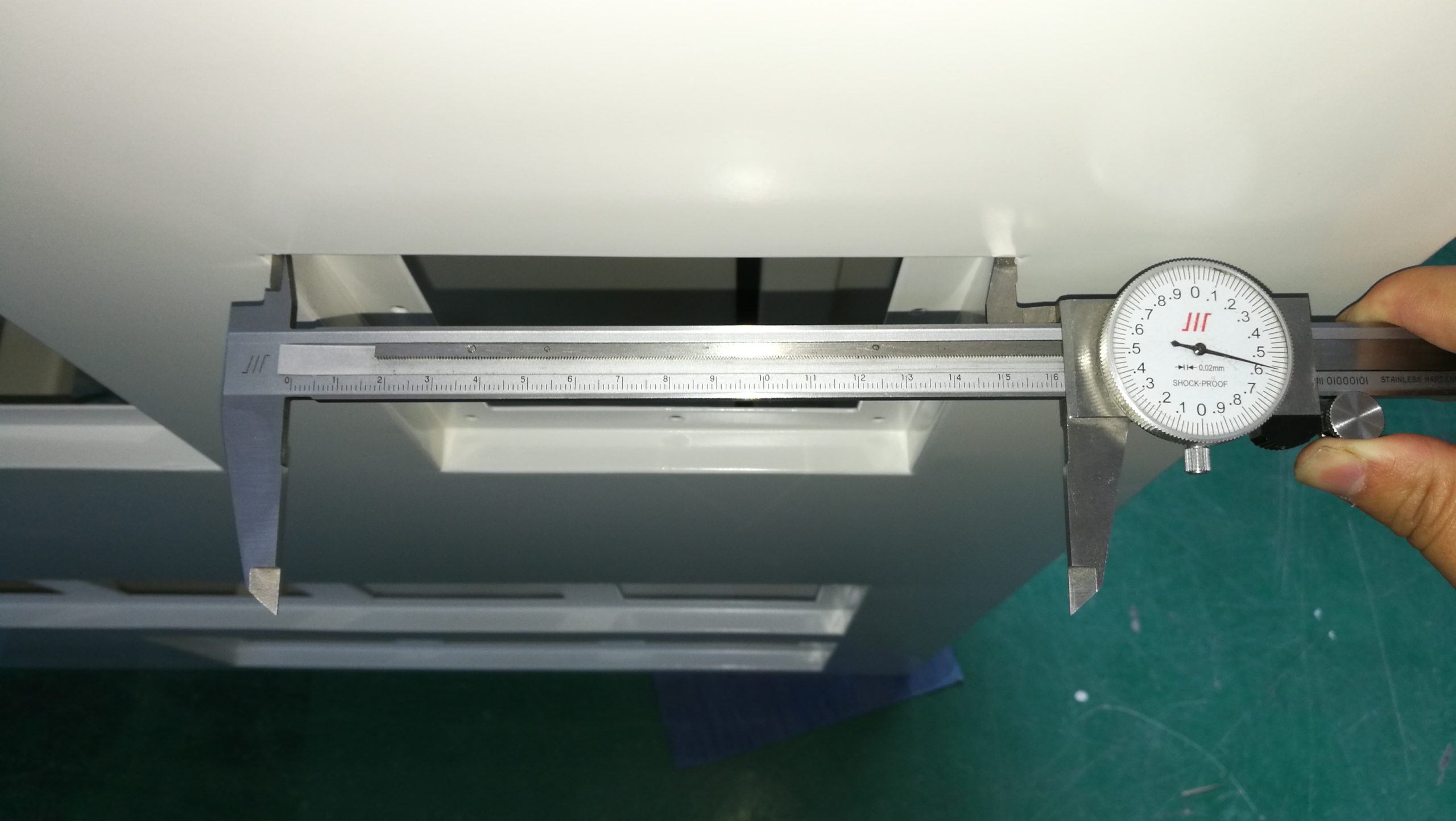

Incoming Materials Check(IQC)

A “0” defectiveness product is realized starting from ideal raw materials. YVLED safeguard our displays’ quality starting from raw materials suppliers. Stay in workshops since the beginning, our egineer staff is experienced to supervise the craftmanship, ensure selected materials be adopted to cabinet frame, modules bracket, work out timely error correction solution, ensure each output is fully qualified.

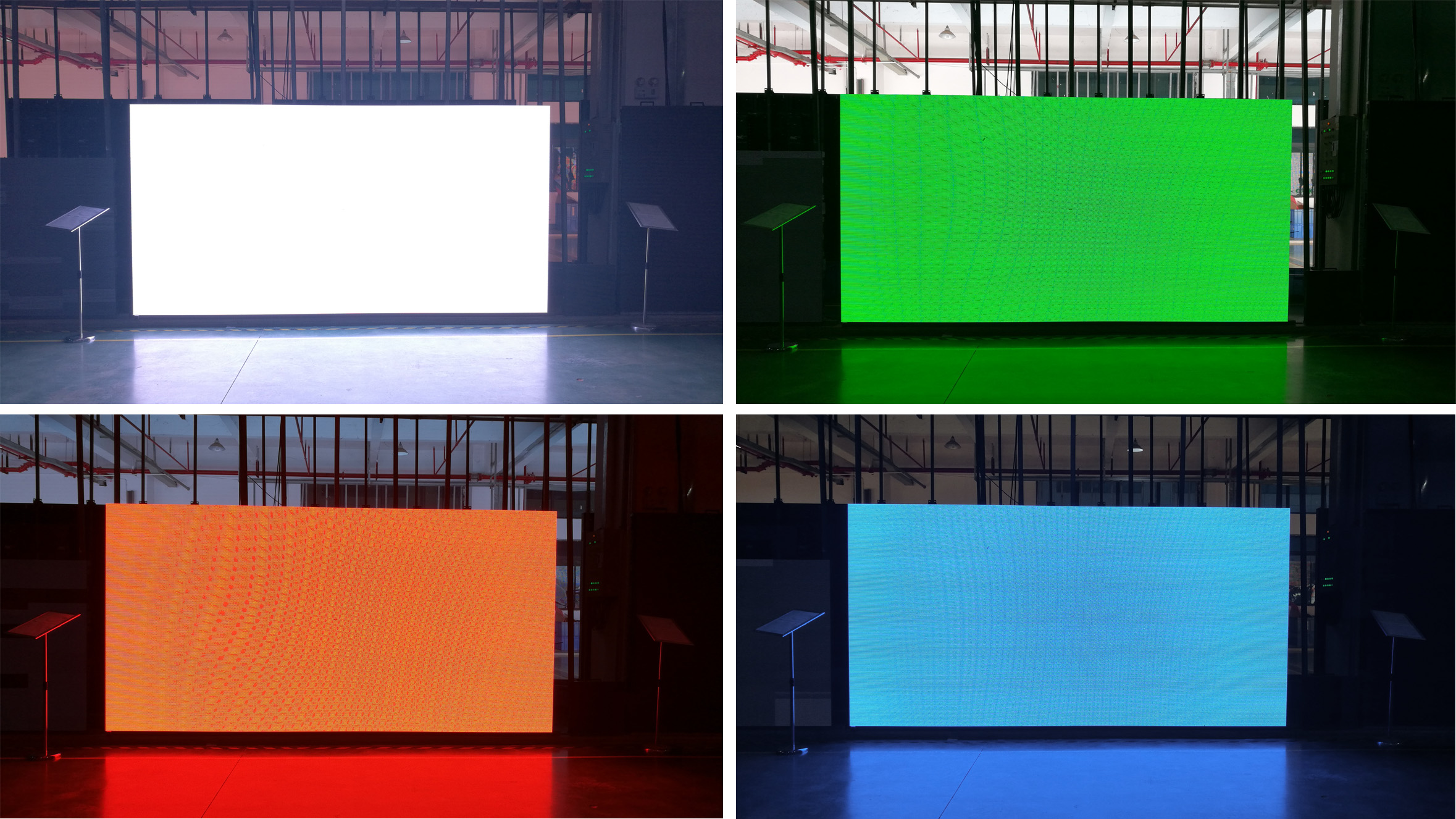

Prototype Testify

Prototype testify is the only way to define the parameter to the displays, such as the current, RGBW brightness, heat-conducting. It is also the scientific way to verify the quality and performance of the final completed display. Through our setup and commissioning to the prototype, we can inject the best visual gene to display. Only a quality passed prototype can step into the SOP.

Flow Supervision (IPQC)

Our production line have checking point for every step particularly SMT period. Highly automatic equipments leads to best reliability and uniformity. advanced inspection machines and methods to ensure no defectiveness will be happened.

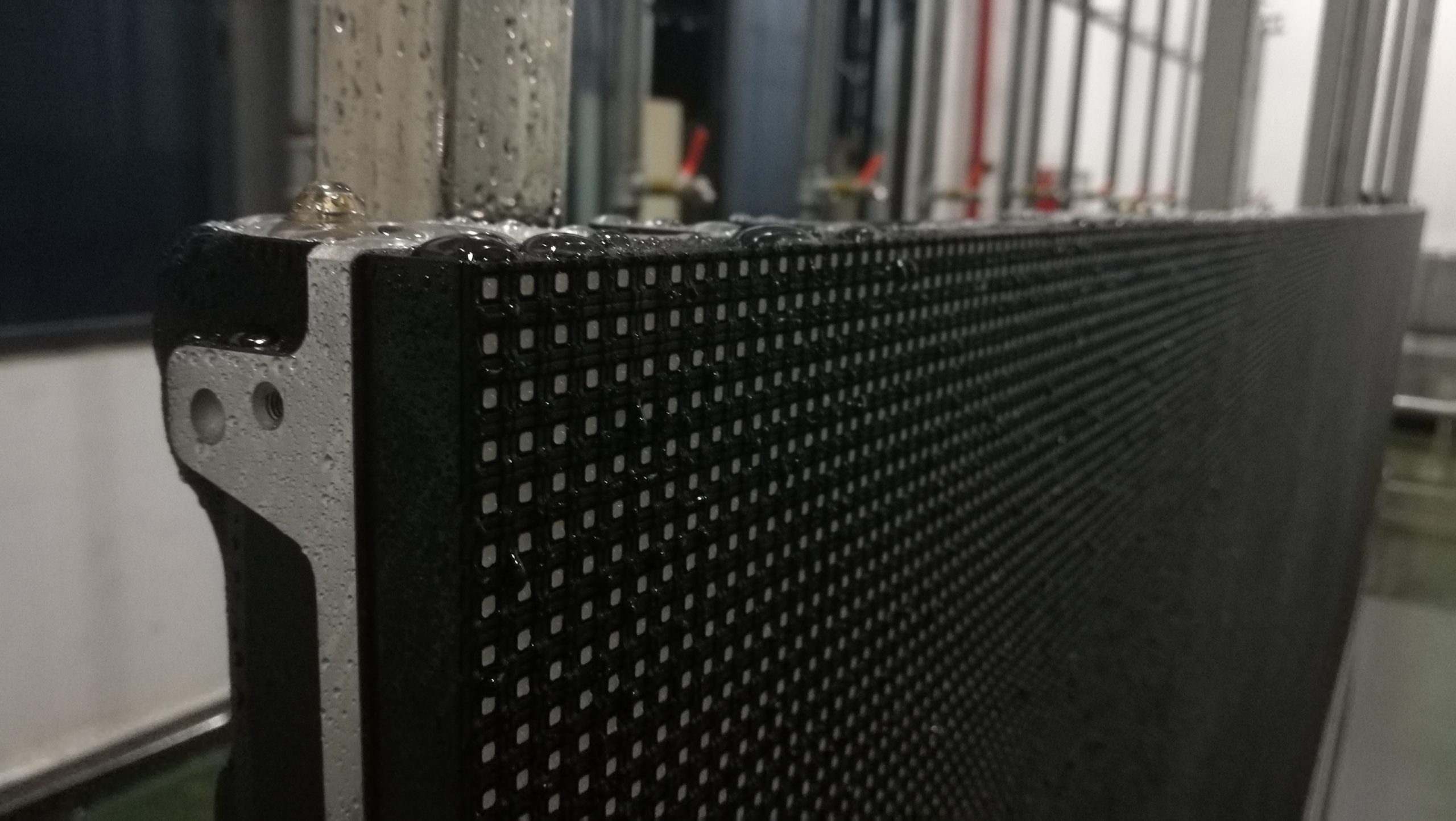

Full Display Aging Test

1. No less than 3 days aging test shall be done to the full display, including grayscale-shifting test, RGBW shifting test, Power on/off impact test, IC circuit test.

2. Commissioning software parameter, work out the optimal visual performance, best color presenting, brilliant brightness.